With the abundance of track days and race meetings around the country today, with two major road racing series and numerous other local club racing and the ever popular track days at virtually every track in the country, track bikes and race bikes in particular need to be prepared properly for their duties on the track. Even your road bike can benefit from lock wiring.

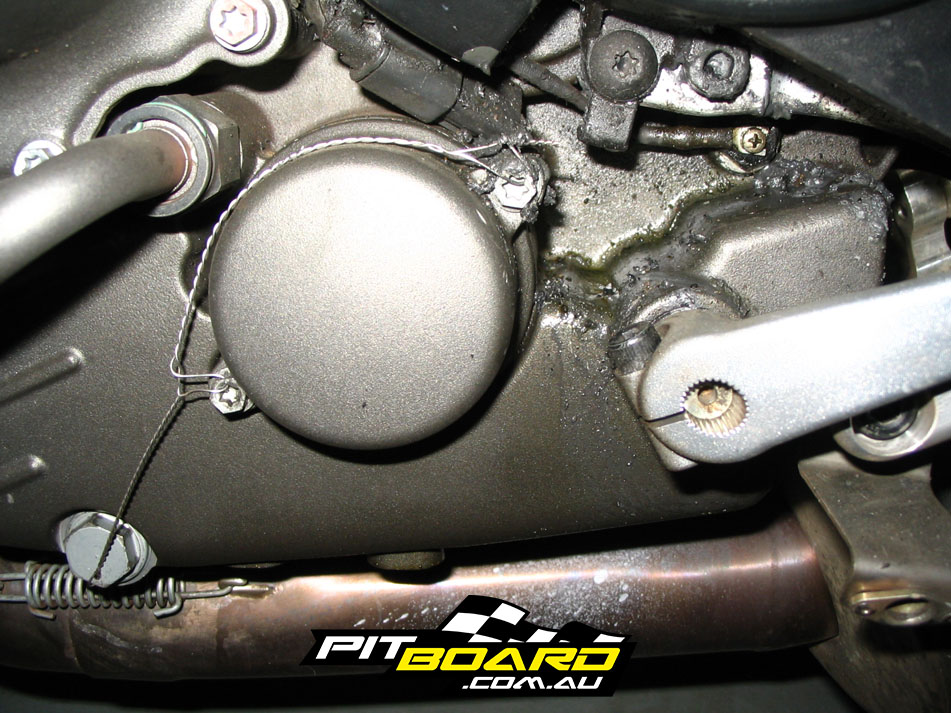

Firstly, any motorcycle used for competition, in our case, road racing, must by National and State motorcycle racing governing bodies standards, have certain parts lock wired for safety reasons. Parts including, drain plugs, oil filters – either spin on type or cartridge type oil filters, filler caps, radiator caps, water overflow caps front brake calliper mounting bolts and any other plug or drain that can allow the escape of any fluid from the motorcycle must be lock wired and inspected before the motorcycle can be used for any competition.

Check out our other tech tips here…

Track bikes, although not race bikes, should still be lock wired. Track bikes are under far more stress over a short period of time than a road bike. Any mechanical device has an inherent vibration or harmonic point that can loosen bolts, nuts and fittings with great ease, everything may be tightened to torque specifications, but with constant high rpm many of these fittings will loosen and can then cause a weep or a spill of fluid.

Obviously any fluid spilt onto a track during racing or track days is a highly dangerous event. It can sometimes take half a lap or more before a rider of a leaking bike may realise he has a oil or fluid leak, or it may cause him or her to crash as a result of the same fluid leak, it can also of course, cause other riders to crash when they run over the spilt fluids. As you can imagine this can seriously delay any racing or any track sessions while the offending fluid spill is cleaned up from the track to then allow racing or track sessions to continue. As a racer and track day manager of Eastern Creek Ride Days I’ve seen the results of these spills in both lost track time, damage to machinery and personal injuries.

By adopting the attitude of safety and lock wiring the motorcycles drain plugs, filters, filler caps and radiator caps; these unnecessary track incidents could almost be eliminated completely. I can hear some of you saying, if I lock wire my road bike, when I sell it people will think it has been raced. It only takes a few dollars to replace the drilled parts with new; no one will really know what you have done. The reality is most race bikes sold as road bikes have had this done already. The benefit is, you have made your bike safer for you for either on the track or road.

Special lock wire tools are available from most good car or bike performance centres. Stainless steel wire of different gauges are available also, but too light a gauge wire may break too easily during fitting, so a reasonably strong wire is best that is also flexible enough to be twisted by the tool.

Once you have identified the bolts and plugs that need to be lock wired, use a sharp drill bit, use either a bench drill (for more control) or a variable speed hand drill to do the necessary drilling of the parts. Try to think about where you are drilling, thinking ahead to where you will attach the lock wire from the part to another securing point on the bike. Try to position the two points so that the plug or part can’t unwind any distance, imagine how the plug would unwind, and attach the wire so it can’t rotate from the locked position.

If you have a spin on oil filter, attach a good quality hose clamp around it and have that clamp pinching the lock wire under it, then you can use the tool to spin the two strands of wire and then attach the wire to another point on the bike, again think about the direction that the filter will unwind and counter that with the anchoring of the lock wire.

The tool is simple to use, cut a length of lock wire, pass it through the pre drilled hole you have created in the plug or part, then double up the wire so you have the two strands next to each other. Hold the wires to where you are going to attach to the frame or other anchor point, at this distance place the tool over the wire and clamp the wires tightly, then lock the pliers shut.

You can then pull on the spiral knob at the end of the plies and they will automatically twist the wires together. Do this a number of times till the wires are twisted like a rope, be careful not to over twist or you will break them and have to start again. Find the anchor point you are using and pass one wire either side of the anchor point and then lock and twist the wires around the anchor point, you can then trim and fold the twisted wires out of the way. You have now successfully lock wired your bike!

Lock Wiring Costs

- Lock wire tool $35 – $70

- Stainless steel wire per container $30

Lockwiring is one of the most important things you should do to your bike before heading on track… Words & Photography: Paul Bailey